I recently uploaded a video describing my design process with a real project that I worked on this summer.

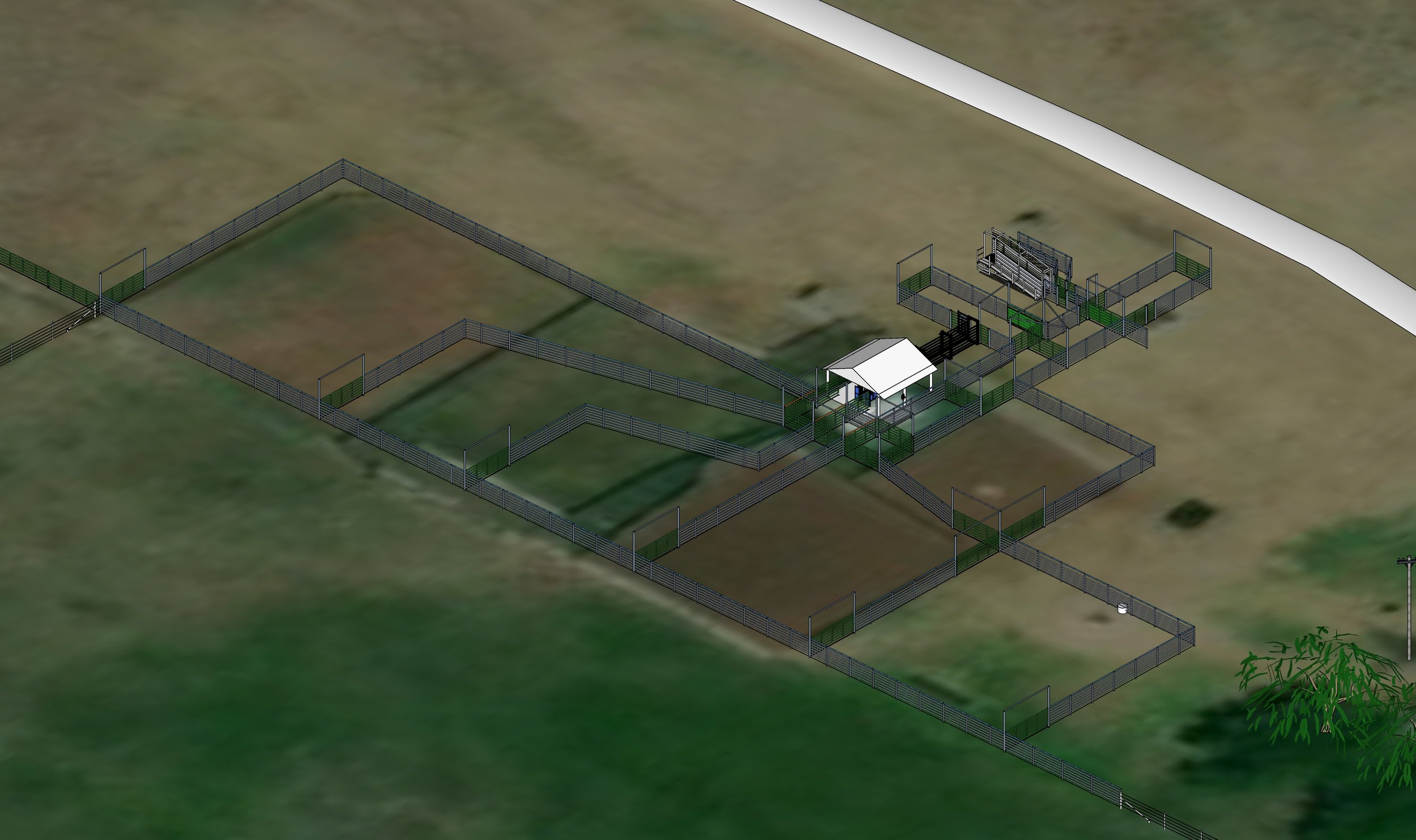

The first step in any design is to familiarize yourself with the location. Mark out the important features. In this project, we had a road that was very important because it determined which direction the trucks needed to be facing when they were loaded.

Next we had a small pole barn with a cement pad that we wanted to reuse. This is a corral that is used in summertime only, so we didn’t need a big building, and it’s a remote location, so reusing a building made sense. There was a small water tank we wanted to incorporate in an external fenceline, and some trees and power line that were far enough away to not be a big consideration. The final feature was the property line that made the southern boundary of the corrals.

the first step is to get familiar with the site you’re designing on. Decide what can be moved, and what you want to save.

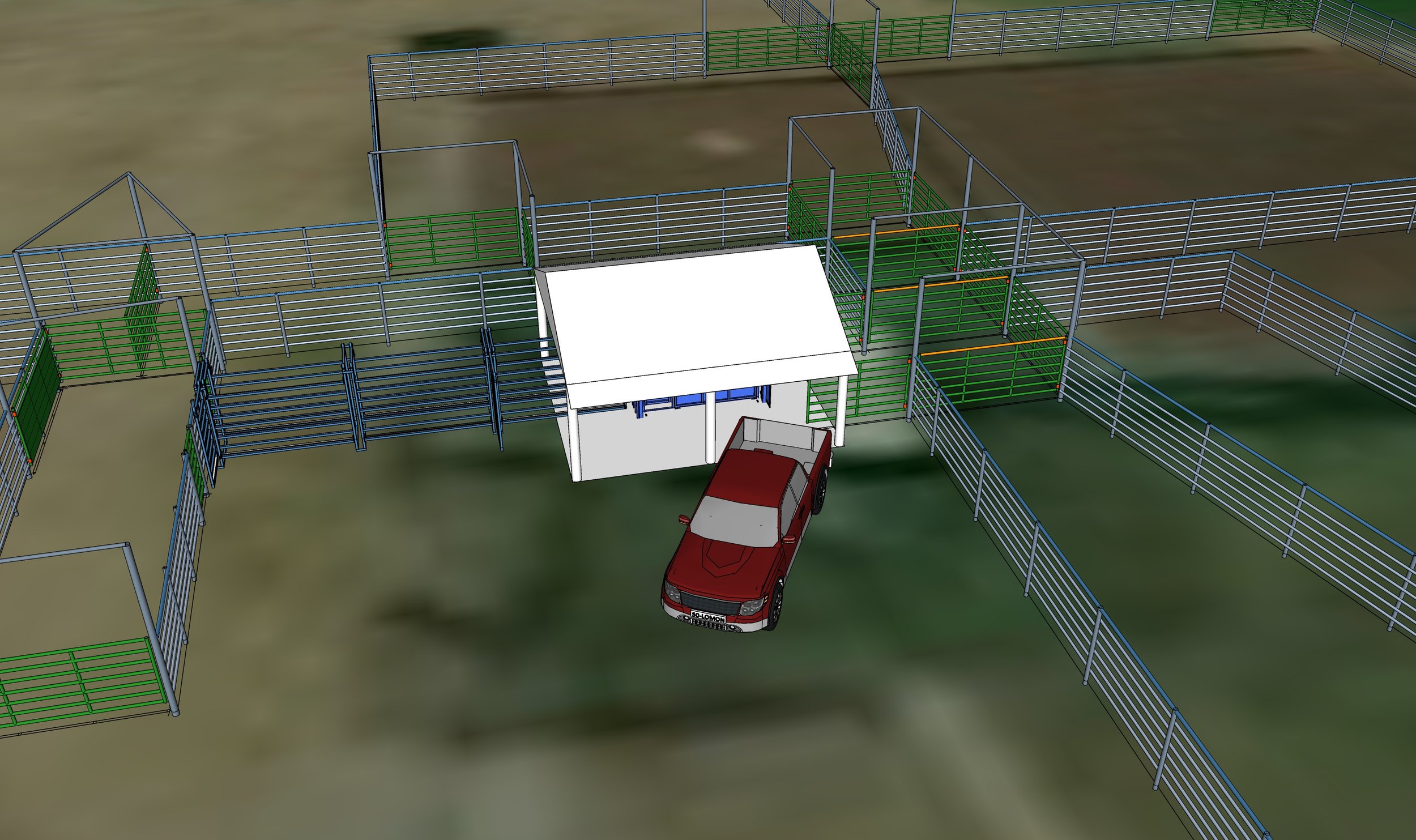

After modeling up the site features, we can figure out where some of the major corral features go. The loading chute needs to go in a certain place so that trucks can be pointed down the road after they are loaded. The working chute has to be under the little pole barn. I decided to face the working chute south so that I’d have more room for sorting pens.

After the working chute nd loading chute are in their required positions, the rest of the corral kind of falls into place.

After those items are in place, the rest of the corral is just kind of connecting the parts together. The holding pens radiate out from the sorting gates. The main holding alley connects the sorting gates to the 2 bud boxes and has gates on the side to allow easy movement from the holding pens. The holding pens all have extra gates to allow easy movement between pen and alley.

Some other features we worked in were to reuse the existing water point, thus saving some plumbing work.

We also made the chute open to the side. By this I mean you have direct access to the chute from the outside, this lets you back your pickup right up to the chute instead of having to carry tools thru gates to the chute. This is a feature I try to work in on every chute that I can. I really like being able to have easy access to the chute. This also lets you add a building much easier later on corrals.

I like being able to access the working chute without going thru any gates.

The final deliverable for a project like this is the 3d model which we did all the design work in, then a dozen or so 2d drawings giving the dimensions of all the pens and showing where things go. Finally, a bill of material that you can use for budgeting and ordering materials.

I hope you’ve found this interesting. If you would like to learn more, feel free to contact me here thru this site.